|

|

|

|||

|

|

|||||

| Building A Fleming That's Right For You - Part 2 | ||||

|

By Ron Ferguson In Part 1, we discussed visiting the shipyard when your Fleming is barely in the build cycle, when there's time to make small changes in layout and options. Here we'll look at a visit at the end of the build cycle. Thursday, February 19, 2009 After our October visit, we made up our minds to return at build completion – if for no other reason than to witness 55-203s nocturnal road trek to the Kaohsiung harbor docks and loading on board the container ship bound for Tacoma. Because Kathryn and I really enjoy learning how things work, the return visit was as much anticipated - maybe more so – than our October visit. This trip would be purely for fun. As we began to make plans for departure, the completion date slipped once more - to February 23rd - with shipping scheduled on the Ever Ulysses, an Evergreen Lines container ship leaving Kaohsiung later that week. By now, construction was far enough along that the date was firm. Departure day finally arrived. Kathryn and I again flew the United Airlines non-stop from Seattle to Tokyo, then another United flight to Taipei where we spent a couple of days. On Sunday, February 22nd, we took the Taiwan High Speed Rail line for the fast 90 minute ride south to Kaohsiung. Early the next morning we were picked up at our hotel for the now familiar drive to the shipyard. Our excitement was high, knowing this time we’d see 55-203 in her completed state. An earlier e-mail explained that she would be shrink-wrapped by the time of our arrival, and I had visions of the winterized boats in the U.S. stored on the hard – essentially a plastic bag with an opening in the transom for access. When we drove into the yard, though, 55-203 looked like she could be put in the water. Closer inspection showed every square inch of the exterior covered with pale blue 12”-wide protective tape. She was sitting on the custom transport trailer, ready for the road trip to the container docks that evening. (Click on any image to enlarge.)  In this light it’s very difficult to even see the pale blue protective tape that envelopes the entire hull.. All that remains is a few hour’s detail work on the interior - and then she’s scheduled for the middle-of-the-night transport to the container harbour.

In this light it’s very difficult to even see the pale blue protective tape that envelopes the entire hull.. All that remains is a few hour’s detail work on the interior - and then she’s scheduled for the middle-of-the-night transport to the container harbour.We were so awestruck at this magnificent yacht that we didn’t even notice at first that the hardtop and radar arch weren’t installed. Due to height limitations for power lines on the nocturnal drive, they would be trucked separately to the container docks, with final assembly done there.  Tony Fleming's new 65-024 is on the left, almost ready for shipment too. Flying Colours 55-203 is on the right - strips of teak battens are strung from the bow over the top of the fly bridge to protect from any wires that might be encountered during the drive to the container harbor. Both yachts are already mounted on the specially constructed I-beam frame they'll ride on across the Pacific, and it's locked down on the transport trailer.

Tony Fleming's new 65-024 is on the left, almost ready for shipment too. Flying Colours 55-203 is on the right - strips of teak battens are strung from the bow over the top of the fly bridge to protect from any wires that might be encountered during the drive to the container harbor. Both yachts are already mounted on the specially constructed I-beam frame they'll ride on across the Pacific, and it's locked down on the transport trailer. The interior of 55-203, with protective tape covering the floor, and the salon settee cushions covered in plastic. The salon table was boxed and stored in one of the staterooms. The pilot house looked even less like it was ready to ship.

The interior of 55-203, with protective tape covering the floor, and the salon settee cushions covered in plastic. The salon table was boxed and stored in one of the staterooms. The pilot house looked even less like it was ready to ship.We immediately went aboard for a tour, going through the areas with Adi where we’d requested custom details. Even though everything was covered in protective tape, we were very impressed with the quality of workmanship, the incredible attention to detail, and just how well thought-out this yacht is. It was difficult to crawl around on the upper and forward decks, as long strips of teak were lashed from the bow to the aft edge of the fly bridge deck to deflect low hanging overhead wires along the road. We inspected the two-stateroom configuration, marveling at the wonderful teak cabinet they'd built to house our stationary exercise bike along the aft wall of the master stateroom. When closed up, it just appears to be a clothes dresser, but the entire wood frame swings out on a large piano hinge, to expose the bike. We really liked the solution they came up with for the washer/dryer, tucked away in the guest head. On the forward deck, Adi showed us the enlarged chain locker to house the extra anchor chain we'd ordered. Frankly, though, the interior looked as if another two weeks would be required to finish up all the details that remained. Adi assured us that 55-203 would indeed be ready for the journey to the container docks at 3AM that night.  With time on our hands, we toured the entire shipyard on our own, visiting each of the production areas. In this photo, we're in front of the hull molds for the Models 55 and 65. Clamoring up the rickety ladders, we then watched fiberglass workers rolling resin to build up layer after layer of fiberglass.

With time on our hands, we toured the entire shipyard on our own, visiting each of the production areas. In this photo, we're in front of the hull molds for the Models 55 and 65. Clamoring up the rickety ladders, we then watched fiberglass workers rolling resin to build up layer after layer of fiberglass. With no one to tell us we couldn't go here or there, we scampered up on hulls fresh out of the molds to watch the workers building bulkheads and laying bilge stringers.

With no one to tell us we couldn't go here or there, we scampered up on hulls fresh out of the molds to watch the workers building bulkheads and laying bilge stringers.After getting back to our hotel for a couple of hours sleep, Adi picked us up at 2:30AM and we drove back to the shipyard. The transport crew was already waiting for us – a semi-tractor hooked up to the transport trailer – and the driver was itching to get underway. Kathryn and I barely had time to snap some quick photos and the caravan started out to the highway. Two shipyard workers were stationed on the Portuguese bridge to deflect low hanging wires across the road. Pilot vehicles were ahead and behind, and we roared out in front in Adi’s car so that we could stop at opportune vantage points to jump out for photographs.  Our drive to the container docks departed the shipyard at 2:40AM, and driving 20kph, we reached the Evergreen Lines security entrance at 4:00AM. Along the way, we encountered low-hanging wires, but without incident - two shipyard workers are standing guard on the Portuguese bridge just in case.

Our drive to the container docks departed the shipyard at 2:40AM, and driving 20kph, we reached the Evergreen Lines security entrance at 4:00AM. Along the way, we encountered low-hanging wires, but without incident - two shipyard workers are standing guard on the Portuguese bridge just in case. A big surprise for us in Taiwan was to see 7-11 stores on almost every street corner - even in the small villages we drove through during transport of 55-203 to the shipyards. We were quite surprised at how aggressively the transport driver handled his rig on the narrow streets and roads out in the countryside.

A big surprise for us in Taiwan was to see 7-11 stores on almost every street corner - even in the small villages we drove through during transport of 55-203 to the shipyards. We were quite surprised at how aggressively the transport driver handled his rig on the narrow streets and roads out in the countryside.By 4:30AM, we were at the Evergreen Lines container docks, and 55-203 was taken to a perimeter area where she would be secure for the next two days. Tired, but elated, we were dropped off at the hotel for some much-needed rest. Sleep was only for a couple of scant hours, though, and by 8:30AM, we were again picked up by Adi and driven back to the container docks to watch the Tung Hwa crew hoist the radar arch, fit the hardtop in place, and wire the overhead lights for the fly bridge. At that point, 55-203 was ready to ship, and was now just waiting for the Ever Ulysses to arrive.  55-203 sits at a quiet sideline area of the container dock, ready for the radar arch and hardtop to be installed.

55-203 sits at a quiet sideline area of the container dock, ready for the radar arch and hardtop to be installed. Once the hartdop is installed, it only takes a couple of hours to finish up overhead wiring of lights and 55-203 will be ready for loading.

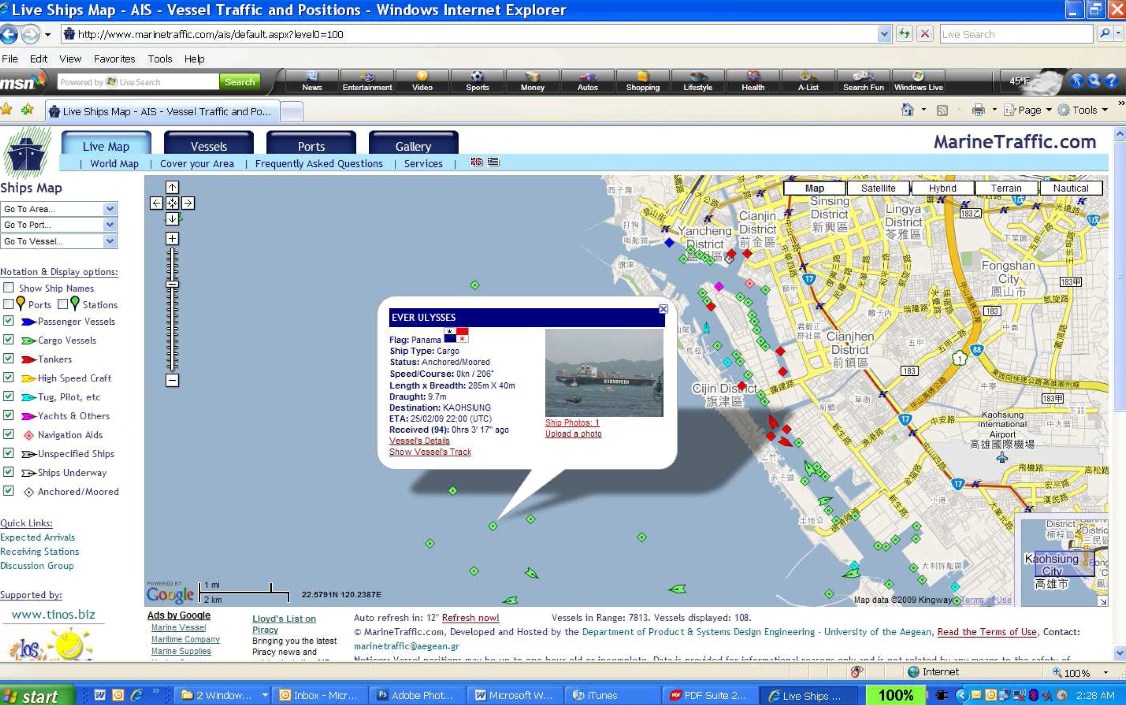

Once the hartdop is installed, it only takes a couple of hours to finish up overhead wiring of lights and 55-203 will be ready for loading.But let’s back up a bit. In early February, curiosity led me to the Evergreen Lines web site. One page listed their shipping schedules, and a link put me at their “U.S. West Coast/Asia/Mediterranean Service” page. I quickly located the Ever Ulysses, scheduled to depart Kaohsiung on February 27th, bound for arrival in Tacoma on March 13th. I’d also learned of a a website called “Live Ships Map – AIS Vessel Traffic and Positions” (www.marinetraffic.com/ais), making it possible to “see” the position of every commercial ship at participating ports around the world. Once at Kaohsiung, from my laptop in our hotel room, I actively watched the AIS website for the Ever Ulysses to arrive. Early on the morning of February 25th, I spotted the AIS tag of the Ever Ulysses, anchored about a mile outside the Kaohsiung harbor. From our hotel room window, I could see her with my high-powered binoculars.  With the AIS tracking website, I could "see" the Ever Ulysses sitting at anchor outside the Kaohsiung Harbour.

With the AIS tracking website, I could "see" the Ever Ulysses sitting at anchor outside the Kaohsiung Harbour. With my high-powered binoculars, I could see the Ever Ulysses sitting at anchor outside the Kaohsiung Harbour, waiting for clearance to dock the following morning. This gave us the remainder of the day to enjoy the sites of Kaohsiung.

With my high-powered binoculars, I could see the Ever Ulysses sitting at anchor outside the Kaohsiung Harbour, waiting for clearance to dock the following morning. This gave us the remainder of the day to enjoy the sites of Kaohsiung.Next morning, the 26th, Adi telephoned to say that loading of 55-203 was scheduled for noon. By now, the Ever Ulysses was moored at the container dock - I’d watched her leave the anchorage from our hotel room window earlier in the morning - and then “watched” her on the AIS website as she made her way through the entrance to the harbor to tie up at the Evergreen Lines container dock. Adi picked us up and drove directly to the container ship. For the next hour, we watched as hundreds of containers were loaded, taking photographs from every angle and aspect of the loading process. We were surprised to be left quite alone, without a security detail watching us, and able to roam around the huge overhead cranes.  On arrival at the Evergreen Shipyard docks, Adi drove us straight to the Ever Ulysses. Loading was already underway, with four dock cranes loading containers aboard.

On arrival at the Evergreen Shipyard docks, Adi drove us straight to the Ever Ulysses. Loading was already underway, with four dock cranes loading containers aboard. We stationed ourselves at the stern of the Ever Ulysses, as 55-203 was supposed to be loaded aboard through an open space about 3/4s aft. This container ship is truly a behemoth, and the stacks of containers far overhead of us looked incredibly tiny.

We stationed ourselves at the stern of the Ever Ulysses, as 55-203 was supposed to be loaded aboard through an open space about 3/4s aft. This container ship is truly a behemoth, and the stacks of containers far overhead of us looked incredibly tiny. Overnight, Tony's new 65-024 was transported to the dock area for sea trials. With Duncan Cowie driving from the fly bridge (and without the radar arch or hardtop on, they brought her right up to the container dock we were at, enabling us to take some photos.

Overnight, Tony's new 65-024 was transported to the dock area for sea trials. With Duncan Cowie driving from the fly bridge (and without the radar arch or hardtop on, they brought her right up to the container dock we were at, enabling us to take some photos.At 1PM, the overhead crane nearest us lifted a half dozen decking platforms into the container ship’s hold, providing the flooring that 55-203 would sit on. One aspect Fleming really likes about Evergreen is their willingness to stow the yacht below deck, reducing the chance for damage - and stays cleaner. In this instance, containers on either side were stacked five or six high above the ship’s main deck, and we knew that 55-203 would be loaded below main deck level, safe and secure from the weather. Finally, it was time for 55-203 to be loaded, and the tractor-trailer rig was brought into position. The crane’s lifting mechanism was lowered to the ground to attach the cable spreader and slings at the four corner points. The cable slings were attached to the cradle, and slowly . . . slowly . . . she was lifted from the tractor-trailer. At about 100’, the crane moved outward towards the open position on the Ever Ulysses.  Our hearts were in our throats as we watched 55-203 slowly being raised into position. About this time, the loading boss came over and invited us to go aboard the Evergreen Ulysses to watch the loading into the hold. We were astonished, and took about 1/2 second to race across the dock.

Our hearts were in our throats as we watched 55-203 slowly being raised into position. About this time, the loading boss came over and invited us to go aboard the Evergreen Ulysses to watch the loading into the hold. We were astonished, and took about 1/2 second to race across the dock. Scrambling up the gangway seemed like duck soup from below, as long as you don't have a fear of heights. It swings and sways under your feet, there's only a very loose rope handrail to hang on to, and through the treads you can see the water far below.

Scrambling up the gangway seemed like duck soup from below, as long as you don't have a fear of heights. It swings and sways under your feet, there's only a very loose rope handrail to hang on to, and through the treads you can see the water far below.To our surprise, the loading boss came over and invited us to board the Ever Ulysses to see exactly where 55-203 was being stored and where she would ride across the Pacific. We had secretly hoped this might happen, but weren’t sure. A second invitation was not necessary, and we sprinted towards the gangway leading up to the main deck of the Ever Ulysses. Once aboard, we quickly descended two or three steep ladders deep into the hold, moving aft along dark companionways that seemed lit by 40 watt bulbs. Finally, we stepped through one last bulkhead - and into sunshine – and there was 55-203 being lowered into place. As we stepped in, the cradle was touching down on the decking plates. We felt like we were in a cavern, with a wall of containesrs stacked seven high all around us. I was amazed to find that the space, horizontally and vertically - equivalent to 32 containers - was taken up by 55-203! It was easy to see why the one-way shipping cost was $40,000. There wasn't much we could do in the way of helping, so we just watched in awe at the immensity of everything around us.

Just as we arrived deep inside the hull of the Ever Ulysses, 55-203 is being gently lowered into place. It takes about an hour to fasten the steel framework she's riding on, and after we leave, a decking plate will be added on top, then seven more layers of containers will be loaded on top of her.

Just as we arrived deep inside the hull of the Ever Ulysses, 55-203 is being gently lowered into place. It takes about an hour to fasten the steel framework she's riding on, and after we leave, a decking plate will be added on top, then seven more layers of containers will be loaded on top of her. As we were getting ready to say goodbye to 55-203 for the voyage across the Pacific, the 2nd Mate of Ever Ulysses, a young Filipino, came over and we got him to pose for a photo with Kathryn and Adi. As we wished him a safe voyage, he invited us to come aboard in Tacoma for the unloading of 55-203. That hadn't yet been arranged, and we figured there was less than a 50-50 chance of it happening.

As we were getting ready to say goodbye to 55-203 for the voyage across the Pacific, the 2nd Mate of Ever Ulysses, a young Filipino, came over and we got him to pose for a photo with Kathryn and Adi. As we wished him a safe voyage, he invited us to come aboard in Tacoma for the unloading of 55-203. That hadn't yet been arranged, and we figured there was less than a 50-50 chance of it happening.Finally, all was secure, and time to say goodbye to 55-203 until she arrived in three weeks in Tacoma. Kathryn and I were completely taken aback at what we’d just witnessed. With the level of Coast Guard and TSA security after 9/11, we figured there’d be little chance of such an adventure when 55-203 was unloaded in Tacoma.  Aboard Tony Fleming's new 65-024, we had a great waterside view of the Ever Ulysses. 55-203 is safely loaded well below the gunwales, in front of the second container row from the stern. Seven more layers of containers will be added on top to fill up that gap.

Aboard Tony Fleming's new 65-024, we had a great waterside view of the Ever Ulysses. 55-203 is safely loaded well below the gunwales, in front of the second container row from the stern. Seven more layers of containers will be added on top to fill up that gap.After disembarking, Adi drove us to a fishing pier near the Evergreen dock, where we were met by Duncan and Tsai with 65-024. We climbed aboard - which was a serious mistake when you've just purchased a Fleming 55 - and we enjoyed a leisurely cruise through the Kaohsiung Harbor. We had a great waterside view of the Ever Ulysses looming over us, and watched as containers were now loaded above 55-203. We cruised the full length of the Kaohsiung Harbour, past dozens of freighters bound for every port in the world. We passed close to the Hotel Splendor, tied the Fleming up at a public pier near a park, and walked into town for a lunch of good British pub food.  Kathryn takes a turn at the wheel of Tony's 65-024 on our hour-long cruise through the Kaohsiung Harbour. It was hard to wipe the grin off her face.

Kathryn takes a turn at the wheel of Tony's 65-024 on our hour-long cruise through the Kaohsiung Harbour. It was hard to wipe the grin off her face. The Hotel Splendor is the hotel of choice in Kaohsiung. The hotel begins at the 60th floor, and being very close to the harbor, you'll want a room with a view in that direction.

The Hotel Splendor is the hotel of choice in Kaohsiung. The hotel begins at the 60th floor, and being very close to the harbor, you'll want a room with a view in that direction.Next morning, we boarded a China Airlines flight to Hong Kong, then connected with a Cathay Pacific overnight flight to Sydney. After what we'd just witnessed, we needed some R&R in one of our favorite cities in the world (Sydney), at one of our favorite hotels in the world (the Park Hyatt on the Rocks). In the morning, it's great for chilling out with a capuccino on the lanai, watching the incredible parade of harbour ferries glide past the Sydney Opera House. We've never before seen sunrises like we did on this visit. In the last installment, we'll greet the Ever Ulysses at the Port of Tacoma, offloading 55-203 for her first dip in the water, and outfitting her at a shipyard along Seattle's Ship Canal. |

||||

| Copyright © 2010 MDT Consulting. All rights reserved. | Visit the Fleming manufacturer's web site | Use & Privacy Policy | Contact us |